Machining

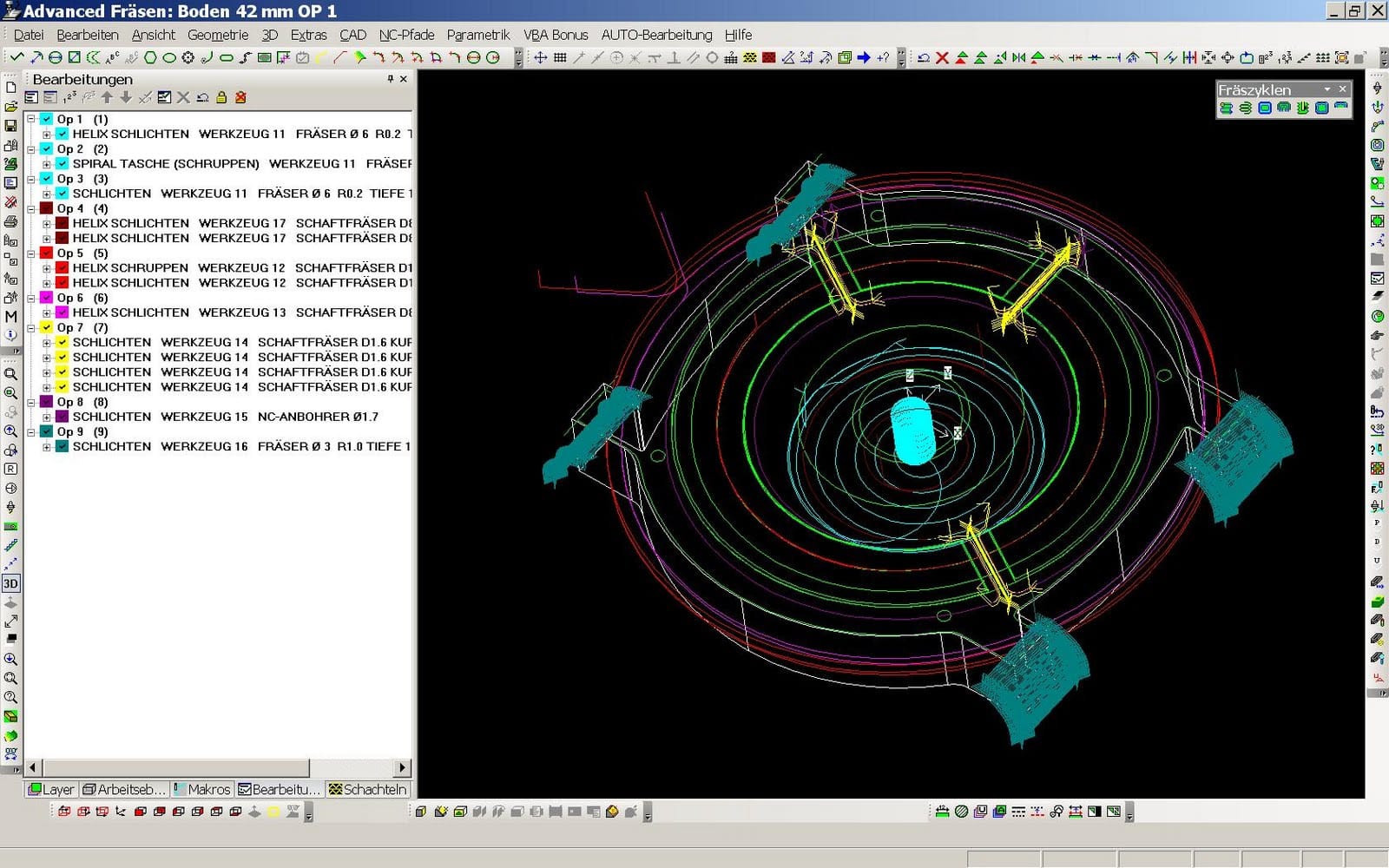

ochs und junior is hard at work machining our new 42mm watch cases. Ludwig has designed a radically simple case that features integrated strap lugs. Four screws attach the middle part to the integrated bezel. The synthetic sealing gasket is pressed on the outside radius of the movement retaining ring. When it comes to the aesthetic-looking silver components of our idea watches, we hand-bond the crystal to the case. Peter Cantieni is so accurate with his milling and lathing and the results are so aesthetic that we don’t subsequently polish the cases. He uses up to 31 tools to mill the contours, with some tools completing up to 2000 movements, each just 0.01mm in depth. Each case involves 38 different operations and one-and-a-quarter hours of machining. This is then followed by the last operation: the hand chamfering of the edges.

The watch movement fits into the case without recourse to a retaining ring. The three indentations accommodate the winding stem and the two tiny screws that attach the movement to the dial. Peter makes the other part of the case on the lathe. Experts will be able to spot the difference in the surface finishes of the case and the bezel.

The end of the month should see the dials ready for the two new watches (one with a date ring, the other with a time ring), at which point they’ll go off to be colour-varnished…

We spent yesterday choosing the colours: light grey, olive gree, dark brown, dark purple and a few other rather adventurous ones… We’ll have some more ochs und junior news for you soon!